Mining, an age-old practice honed through millenniums, remains to this day a cornerstone of society, unearthing essential resources and minerals to be used in developing a multitude of economies and industries. At the core of this success are the gargantuan mining pieces of equipment deployed at the forefront of these mining operations.

The mining equipment here is a reflection of human ambition and skill. From behemoth haul trucks to colossal excavators, these industrial giants not only form the landscape but also push the limits of engineering marvels. Come along with us as we venture on a trip to discover the biggest, baddest, and without a doubt, coolest mining gear ever made.

This article will take us into the world of mining titans, where we will witness their mind-blowing size, strength and importance in the modern mining industry. Prepare to be enthralled as we pull the curtains up on the great machines which epitomise mining excellence.

Top 10 Biggest Mining Equipment

Bagger 293 – The Brobdingnagian Bucket-Wheel Excavator

Height: 96 metres | Length: 225 metres | Weight: 14,200 tons | Capacity: 240,000 cubic metres of earth per day

Created by TAKRAF, a German industrial company, in 1995, the Bagger 293 is currently the largest terrestrial machine. Surprisingly, it only requires 5 crew members to operate. Equipped with 18 buckets, each being able to hold 15 cubic metres of material, the Bagger was reported to be able to move 240,000 m3 or 218,880 tonnes of soil per day.

Moreover, this machinery is taller than the Statue of Liberty and heavier than the Eiffel Tower. Any conversation about the biggest mining equipment would feature this iconic titan.

It is currently operating at a brown coal mine in Germany, owned by RWE Power AG.

BelAZ 75710 – The World’s Largest Colossal Haul Truck

Payload Capacity: 450 metric tonnes | Engine Power: 4,600 horsepower | Length: 20.6 metres | Curb Weight: 360 tonnes

Manufactured in Belarus by BelAZ, the 75710 is considered the world’s largest, highest payload capacity haul truck. To put it into perspective, the 75710 can carry the equivalent of around 80 average-sized adult male African elephants!

One of the greatest attributes of this truck is its power efficiency. It has two 16-cylinder four-stroke diesels that each deliver 1,715 horsepower and create electricity to power four electric motors, these can run at a top speed of 64kph.

Moving such large payloads is a fuel-consuming process, and the diesel intake for the 75710 is approximately 1,300 litres every 100 km but can be run on one engine when it is not loaded to save fuel.

Overburden Conveyor Bridge F60 – The Lying Effiel Tower

Length: 502 metres | Width: 241 metres | Height: 79 metres |Curb Weight: 13,600 tonnes

The F60 was built and manufactured in Germany by TAKRAF GmbH Launchhammer between 1969 and 1991; it’s deployed to brown coal opencast mines throughout Germany. These machines are considered the largest movable technical industrial machine in the world. These behemoths are longer than the Eiffel Tower by a staggering 182 metres and are often compared, being dubbed the ‘Horizontal Effiel Tower’ due to their size and similar design. It is also equipped with two bucket wheel excavators, theoretically able to move 29,000 m3 of overburden in an hour. This is equivalent to filling a whole football stadium up to a height of 8 metres with overburden!

Liebherr T 284 – The Ultra-Class Haul Truck

Payload Capacity: 363 metric tonnes | Engine Power: 4,000 horsepower | Gross Power: 3,000 kW | Weight: 617 tonnes | Length: 15.7 metres

Manufactured by Liebherr as a successor to the T 282 series ultra-class haul truck. The T 284 has the largest payload capacity of its class. It has a monstrous engine – at over 4,000 horsepower; the pulling power is immense, theoretically being able to tow a line of 33 double-decker buses. Its fuel consumption is significantly better than the T 282, positioning the T 284 as superior in not only just horsepower and payload capacity but also in terms of fuel efficiency.

Caterpillar 797F – The Ever-Reliable Haul Truck

Payload Capacity: 400 tonnes | Engine Power: 4,000 horsepower | Length: 15.09 metres | Height: 15.7 metres

The Caterpillar 797F represents the pinnacle of Caterpillar Inc.’s engineering capabilities. Introduced into full production in 2009, it stands as the largest, high-capacity haul truck in their series. The 797F boasts an engine power of 4,000 horsepower and a top speed of 68 km/h while hauling heavy payloads. It is thus an indispensable machine for any mining site. Furthermore, its frame, powertrain, engine, and components are meticulously designed with rebuildability in mind. This deliberate design means that the shelf life can be stretched a lot more at a significantly cheaper price compared to purchasing a new truck. Notably, the 797F is the only machine of its size class to achieve the milestone of 130,000 hours, a testament to its outstanding long life and durability.

In addition to this, part manufacturers are crucial as a result of the high-stress trucks may take in certain environments. Mammoth Mining Machinery Equipment manufactures OEM replacement parts compatible with the 797F and other mega machinery, ensuring seamless maintenance and extended operational efficiency for mining operations.

Sandvik DR416i – The Lean, Mean, Blasthole Drilling Machine

Hole Diameter: 270-406 mm | Maximum Depth: 42.4 metres | Weight: 215,450 kg | Engine Power: 1,118 kW/ 1,500 hp

The Sandvik DR416i is a diesel-driven juggernaut amongst the surface mining machineries. It is considered the largest blasthole drilling rig. This self-propelled beast not only has a smart hydraulic system, that is controlled through a Control Area Network (CAN) bus but it also has a real-time monitoring system which makes sure that this colossus functions perfectly with minimum downtime.

The DR416i is not only just powerful, it is eco-friendly as well. Sandvik’s Compressor Management System cuts down on fuel consumption by 35%, leading to fewer emissions that minimise the environmental impact and prolong the life of the engine. This led to the DR416i being viewed not only as a reliable option for mining operations but also as a sustainable one.

Finally, it is accurate to say that the Sandvik DR416i is the top surface drilling technology in the market. Taking into account its combination of power, efficiency, and sustainability, this technology is a perfect candidate to spearhead the mining industry’s search for sustainable and high-performance operations.

Herrenknecht S-880 – The Mega Tunnel Boring Machine

Shield Diameter: 17.63 metres | Length: 120 metres | Weight: 4,850 tonnes | Cutterhead Power: 5,600 kW | Torque: 27,722 kNm

The Herrenknecht S-880, also known as “Qin Liangyu,” is the largest tunnel boring machine in the world, awarded by the Guiness World Records, designed by German tunnel boring machine manufacturer Herrenknecht AG. This machine is designed with the special feature of operating in waterlogged soil under the oceans and rivers. It consists of a circular rotating cutting face with enclosed machinery behind it that transports away the overburden and stabilises the dugged tunnels.

When in operation the S-880 must be pressurised to eliminate the possibility of tunnel flooding; while behind it, a watertight lining of grout and precast interlocking concrete blocks is installed.

Amongst other things, the Herrenknecht S-880 played a major role in the excavation of the Chek Lap Kok to Tuen Mun subsea road tunnel in Hong Kong, China, which is a testament to its unrivalled performance in a complex subterranean environment.

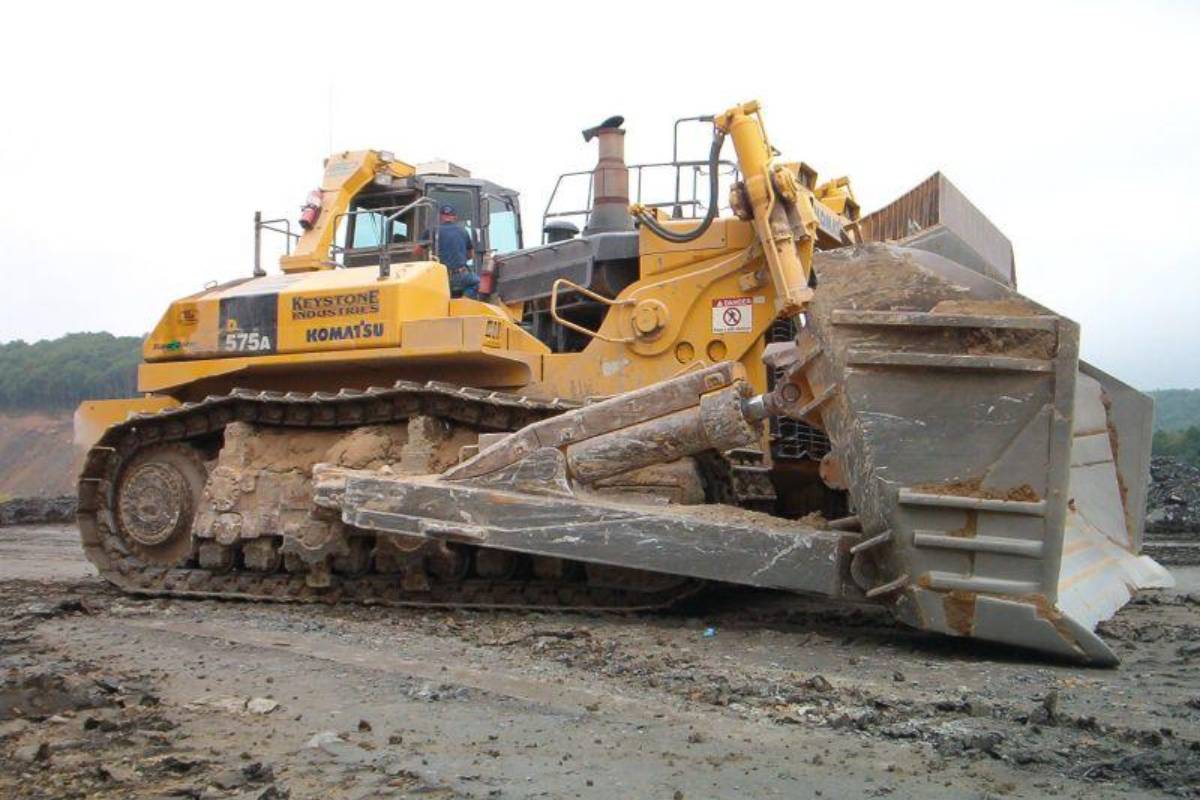

Komatsu D575A-3SD – The Bulldozer With Authority

Blade Capacity: 69/96 cubic metres | Engine Power: 1,150 horsepower | Operating Weight: 152 metric tonnes | Width: 7.4 metres |Length: 11.71 metres

Commonly referred to as the world’s largest production bulldozer, the Komatsu D575A-3SD is a tractor crawler configured in the Super Dozer (SD) profile and is a colossal reminder of the technological and engineering marvel of humankind. This dozer can move up to 69 m3 of material per pass. However, this drill boasts the possibility of being fitted with an optional blade that highlights the real prowess of the D575A-3 SD since this model now has the increased capacity of up to 96 m3 per pass. Such an enormous undertaking could be visualised as the daunting job of moving rock, soil or any sediment your fancy from a large studio apartment, with an area of 30 feet by 30 feet. The Komatsu D575A-3SD makes short work of clearing this substantial volume in just a singular pass, showcasing its remarkable capability for efficiency in handling a vast amount of material it will constantly have to deal with during mining operations.

Sandvik MT720 – The Legendary Roadheader

Cutting Power: 300 kW | Weight: 135 metric tonnes | Maximum Cutting Height: 6 metres | Cutting Speed: 1.4 m/s | Dimension (L x W x H): 20.0 x 4.62 x 5.18 m

Sandvik’s roadheaders are equipped with high-performance transverse cutter heads with each being a product of precise design and ingenuity. A wide range of rock conditions can be overcome by the cutter head without any problem. Whether it be road tunnels, shaft sinking or the excavation of underground caverns, these machines stand out in terms of versatility and productivity.

The Sandvik MT720 is a crawler-mounted boom-type electric machine specifically engineered to work even in rock types that are hard and abrasive wherein compressive strength goes above 120MPa for mechanised tunneling tasks. Having a mass of 140 tons, this roadheader is equipped with a powerful telescopic boom and a serious transversal cutter head that enable precise and strong excavation. The MT720 features a tough design and is equipped with the latest ICUTROC© cutting system that is highly suitable for the hard rock sites which demands reliability and low operation cost to effectively excavate. Being a go-to brand on the market, Sandvik roadheaders are backed by different digital innovations that deliver additional value in the prevailing high-demand market.

It is then of no surprise that this behemoth is considered the strongest roadheader in the world.

Credit: Wikipedia

| Honourable Mention | Acco Super Bulldozer – The Sleeping Titan

Lenght: 12 metres | Weight: 183 tonnes | Engine Power: 1,350 hp | Blade Width: 7 metres | Maximum Payload: 99.7 tonnes

While its mining workhorse that has not been field-tested, the Acco Super Bulldozer stands out as a sleeping titan, showcasing exceptional power and capabilities that earn it a place of recognition among the giants of heavy equipment.

The Acco Super Bulldozer, also known as the Acco BD-30, is a gigantic and very powerful one-of-a-kind heavy machinery that have garnered popular for its remarkable features. Originally manufactured in the 1980s by Italian contractor, Umberto Acco, this beast of a dozer was manufactured for earthmoving and land clearing in Libya. Though it never was shipped to its intended destination.

The most distinguishing feature of Acco Super Bulldozer is absolutely its jaw-dropping size. This 12-metre long behemoth with a staggering 183-ton weight is still considered the largest bulldozer in the world. Its colossal size and heavy-duty design enable it to withstand tremendous work pressures.

Although Acco Super Bulldozer has not been implemented for mining purposes, it is still considered a symbol of outstanding engineering and innovation. The vehicle’s extraordinary specifications and unparalleled capabilities have bestowed it with an almost revered status among enthusiasts and industry professionals; it stands undoubtedly as the giant of earthmoving world.

Conclusion

Through this article, we’ve become witnesses of the variety of outstanding machines that significantly challenges the frontiers of technical possibility. From the gargantuan Bagger 293 to the mighty Caterpillar 797F, each machine displayed in this article are the best mining machines the industry has to offer

These industrial giants whether transportation materials, excavating earth or drill through impregnable rock are the backbone of the mining that supply all of the world’s economies and development. In a true sense they are the unique manifestations of our ability to imagine, design, realise, and dream.

As we conclude our investigation of the biggest and baddest mining equipment, one thing becomes abundantly clear: these tools are more than just machines to the mining industry; they are not only the backbone but also the face what the mining industry has evolved to in modern times.

Therefore, while we stand in admiration of the grandeur of the heavy equipment that enables mining operations to be industrialised and efficient as it is today, we should also remember and appreciate the meticulous work of the engineers, designers, and operators that make them so.